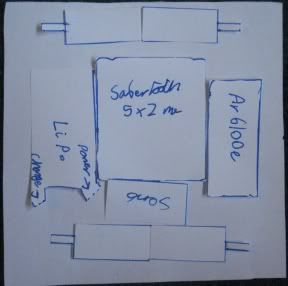

It will have:

4 motors (I will try to link them sometime)- 2 per channel

Sabertooth 5x2 dual motor controller

7.2V LiPo

AR1600e Spectrum receiver

A servo (not sure what yet but I want it to be quick for the flip)

1-3mm Polycarbonate, 1-2mm Aluminium front

(front)

(back)

Just to note the servo is vertical not lying down to give it more clearance for the flipper over the motors and saber tooth. The rest of the robot will be very flat.

It should have nice pushing ability with fliping aswell. And looks to be under weight so far. What would a solenoid be like powering the flipper. Amd if a servo is better how to arrangee it? Direct link or other mechanism.