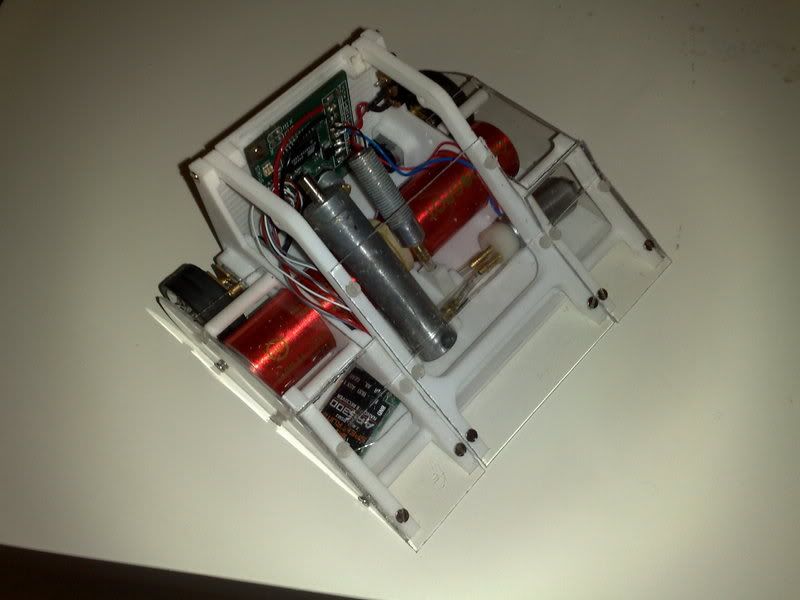

The parts inside anticide are quite old now, i bought them way back for aws17.

The current version parts and weights are as follows.

Drive Motors

2 HP pololu motors (originally 50:1 not sure now i think one is 30:1)

20 g

http://www.pololu.com/catalog/product/998

Controller board

Barello ant 150 (Very heavy control board outdated now but has 3rd analogue output to control solenoid valve. This could be done easily with a simple rc switch)

14g

http://www.barello.net/ANT/150manual.pdf

Battery

3 cell 130mah battery from atomic workshop (Not the cheapest cells but nice C output)

11g

http://www.atomicworkshop.co.uk/catalog ... 6d74d99e1b

Air Tank

2 Gold Spot Breath Freshners (They were emptied, tops removed and joined end to end with a aluminium tube. A hole was drilled in the middle and a 2mm brass tube inserted as an input)

14g

Avaliable from lots of places, i got mine from ebay

Pneumatic Ram

1" stroke ram (Bought as a kit from when robotcombat sold pneumatics, made by robart)

20g

Avaliable in the uk http://technobots.co.uk/acatalog/Online ... s_144.html

Fill Valve

A one way valve used to pump up the pneumatics. Also bought from robotcombat, not sure about suppliers now other than robart.

4g

http://robart.com/air_systems/access.aspx

Solenoid Valve

A 3/2 valve called Hi-flow by inertia-labs. I have been looking for an alternative supplier however i haven't found one so the new one will use a different valve.

18g

This is a data sheet of something very similar

http://www.ascovalve.com/Common/PDFFile ... 407CR4.pdf

Tubing

Same as the one sold by technobots. About 3cm used in total

1g

Switch

Maplin slide switch

1g

http://maplin.co.uk/Module.aspx?ModuleNo=2476

Reciever

Spektrum AR6300

3g

lots of shops sell this. http://www.spektrumrc.com/Products/Defa ... =SPMAR6300

Wheels

Covered with lint roller

6g

Chassis

3D printed from shapeways.com

24g

Armor

Folded and bolted together 1mm polycarb

15g

Total 152g

=======================================================

So how to improve these parts and the impacts on the robot.

More powerful ram

More pressure: Not allowed due to pressure rule

Larger bore: more space in robot, uses more gas. Weight?

Faster actuation

More pressure: Not allowed

More flow: larger bore pipes, higher flow 3/2 valve as that is the limit point of flow

More flips

Larger storage: More volume in robot, weight?

Shorter Stroke ram/Less pipes: weight saving? Effectiveness of flip/self righting

Lighter parts

Lipo: could be 2 cell

Control board: could be replace with a smaller drive board

ram/valve: are the 2 heaviest parts of the robot and could be reduced

Armour

I have taken a lot of damage from spinners in the past - Weight!

Flip

Anticide does tend to flip robots up or backwards rather than forwards. I would like to try and improve the forwardness part of the flip but not sure how to achieve this yet.

=======================================================

Alternative parts:

Lego

After Snibston Scott and I did some tests with lego pneumatics. The lego pipes blow off at ~40psi which is lower than the allowed 100psi. Using higher pressure tubing with the same diameter (4mm outer 2.5mm inner) the pressure can be increased. Both the large bore ram and small bore ram can hold 100psi without leaking. The lego mechanical valve leaked at above 60psi. We also tried making a compressor using the small lego pump however this couldn't pump over 40psi.

The lego pneumatics have pin hole sizes limiters at the ports which can be drilled out up to 2mm. However for the valve this requires disassembly which can be difficult to reassemble correctly.

From these tests with the drilled out ram and re-lubricated at 100psi when activated the top flew off due to the speed and pressure increase. Therefore the top may need to be epoxied on, although the lifetime maybe reduced.

The lego ram seems like a good option at this point, a slightly larger bore ram with higher flow than the current version. However the lego valve can't handle the pressure so an alternative needs to be found.

fischertechnik pneumatics

I haven't had much time to play arround with these, however they seem to run on ~15psi. They are very low friction rams and have very neat valves. However the force and speed looks very low.

Valve

Finding a valve to replace the current solenoid valve has proven very difficult. Valves designed to run on higher pressures have less flow. And most solenoid valves are large and heavy. The only alternative i have found which looks reasonable is this one from RS http://uk.rs-online.com/web/search/sear ... &R=2898736. This takes the 4mm tubing similar tot he lego valve and has ~3 times the flow of the current valve. It is mechanical so requires a servo to activate it which requires a little more designing.

=======================================================

So this is where i am up to now:

Lego ram 11g (9g saving)

RS valve with small servo 10g (8g saving)

baby-orangutan control board 4g (10g saving)

possibly 2 cell lipo (4g saving)

redesigned tank (1-2g saving)

I would like to reduce the size of the fill valve as well but haven't found a nice alternative.

=======================================================

So feel free to add pneumatic parts to this thread for anyone who would like to build a pneumatic flipper.