New Featherweights

Moderators: BeligerAnt, petec, administrator

- Marco Roberts

- Posts: 336

- Joined: Sun Jun 23, 2002 12:00 am

- Location: London

- Contact:

Ha good ole leo and mario to back me up. Yeah its soft and the taps will bore out.

I use self tapping screws which work well. But as I said, I find it hard to do anything too acurate it usually bends out of shape.

But apart from that lil issue I love the stuff.

Hence me building a heavy out of it.

I use self tapping screws which work well. But as I said, I find it hard to do anything too acurate it usually bends out of shape.

But apart from that lil issue I love the stuff.

Hence me building a heavy out of it.

<-=AWS 10 1st and 2nd champ=->

<-=AWS 13 1st and 2nd champ=->

<-=AWS 13 1st and 2nd champ=->

I thought I mentioned this earlier- obviously not

The only reason that it is tapped together at the moment is because it it my D.T project for school and I need it to be finished by next week.

It will not be fighting until it has been marked and after that it will be welded together to increase the strength- the taps are only a temporary way of holding it together.

The side panels are held in place with some polycarb blocks mounted inside which the panels screw into.

Also to stop the chassis flexing it is being supported with several titanium plates.

I am currently uploading some pics of the finished chassis onto my photobucket account which can be found here- http://s216.photobucket.com/albums/cc27 ... 0Wave%202/

I will certainly be glad to get this one finished and submitted so that I can get Whirlpool and Shockwave upgraded for the UK championships.

The only reason that it is tapped together at the moment is because it it my D.T project for school and I need it to be finished by next week.

It will not be fighting until it has been marked and after that it will be welded together to increase the strength- the taps are only a temporary way of holding it together.

The side panels are held in place with some polycarb blocks mounted inside which the panels screw into.

Also to stop the chassis flexing it is being supported with several titanium plates.

I am currently uploading some pics of the finished chassis onto my photobucket account which can be found here- http://s216.photobucket.com/albums/cc27 ... 0Wave%202/

I will certainly be glad to get this one finished and submitted so that I can get Whirlpool and Shockwave upgraded for the UK championships.

Progress report

Tidal Wave 2 is almost finished, I had a few hours fitting all of the parts today. Drive is in and so is most of the pneumatics- a bit of wiring and plumbing left to do before it is submitted on friday but that won't take too long.

Then all I have to do is get the logo laser cut for the flipper and fit the light up rear spikes.

I will upload loads of pictures this weekend.

Tidal Wave 2 is almost finished, I had a few hours fitting all of the parts today. Drive is in and so is most of the pneumatics- a bit of wiring and plumbing left to do before it is submitted on friday but that won't take too long.

Then all I have to do is get the logo laser cut for the flipper and fit the light up rear spikes.

I will upload loads of pictures this weekend.

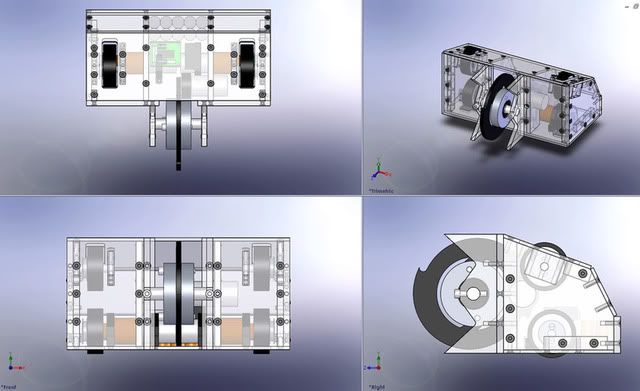

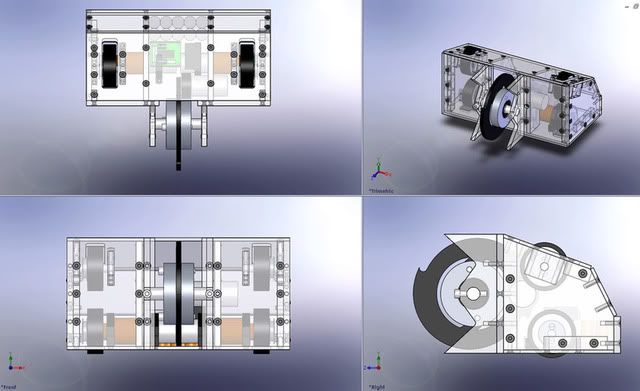

I'm mostly into antweights, but lately I've been designing my own Featherweight, which is an uppgrade of my prevoius attempt. But for now all I got is a CAD, which look pretty much the same when finished.

Some spec:

Name: Accident.

Status: Under construction.

Weight: ~9-10Kg according to CAD

Drive: 2 x 12V drill motors, Sabertooth Dual 10A.

Power: 12-14.4V NiMH 3800mAh Sub C cells (http://stores.ebay.co.uk/All-Battery-Center)

Chassi/Armour: The entire bot will be made with HDPE with some Lexan trims.

Weapon: 180mm Hardox 650 disc

Some spec:

Name: Accident.

Status: Under construction.

Weight: ~9-10Kg according to CAD

Drive: 2 x 12V drill motors, Sabertooth Dual 10A.

Power: 12-14.4V NiMH 3800mAh Sub C cells (http://stores.ebay.co.uk/All-Battery-Center)

Chassi/Armour: The entire bot will be made with HDPE with some Lexan trims.

Weapon: 180mm Hardox 650 disc

-

Glenn Jones

- Posts: 37

- Joined: Thu Jan 18, 2007 4:34 pm

- Location: Assen, Holland

I finally got round to testing Tidal Wave 2's flipper.

I had it driving the other day and I have just tested the pneumatics.

It can easily match Shockwave's flipping power on 10 bar and on 16 it was much better. The system can go as high as 22 bar but it started to rain so I didn't have time to test it fully.

As I said before it will eventually be full pressure- The current ram is a FP one from beauty so it's just a case of upgrading the rest.

The specs have changed a little since last time:

Weight- roughly 11kg at the moment

Length- 53cm

Width- 50cm

Height- 20cm

Drive- 2x MFA motors running at 24v on 70mm wheels

Batteries- 2x 12v Ni-Mh

Speedo- will eventually be a scorpion XL or a sabretooth

Weapon- 16 bar CO2 flipper with a 50mm bore ram, 1/2 inch burket style valve with buffer and 1 of Trevor Wrights regulators.

Armour- a mix of 6mm, 8mm & 10mm HDPE with polycarbonate supports and 1.6mm titanium blade and stiffening plates

I have a couple of videos of the testing which will be put online as soon as i get them off of the camera

I had it driving the other day and I have just tested the pneumatics.

It can easily match Shockwave's flipping power on 10 bar and on 16 it was much better. The system can go as high as 22 bar but it started to rain so I didn't have time to test it fully.

As I said before it will eventually be full pressure- The current ram is a FP one from beauty so it's just a case of upgrading the rest.

The specs have changed a little since last time:

Weight- roughly 11kg at the moment

Length- 53cm

Width- 50cm

Height- 20cm

Drive- 2x MFA motors running at 24v on 70mm wheels

Batteries- 2x 12v Ni-Mh

Speedo- will eventually be a scorpion XL or a sabretooth

Weapon- 16 bar CO2 flipper with a 50mm bore ram, 1/2 inch burket style valve with buffer and 1 of Trevor Wrights regulators.

Armour- a mix of 6mm, 8mm & 10mm HDPE with polycarbonate supports and 1.6mm titanium blade and stiffening plates

I have a couple of videos of the testing which will be put online as soon as i get them off of the camera