Reading on the internet it appears supporting nylon is generally a problem as nylon doesn't stick to much other than itself.

I have tried using the same nylon as a support on the I3 but at the temperatures needed to give good inter layer bonding it is difficult to separate the model from the support.

To get the nylon to stick to the glass table I use a PVA glue stick so that suggested that nylon should stick to PVA plastic so I ordered a sample of Kai Parthy HIGH-T-LAY which is a PVA based water soluble support material. While waiting for that to arrive I thought I would try using a slightly different nylon as a support material. I had noticed that at lower temperatures the nylon loses its inter layer bonding so I ran with Taulman t-glase nylon as the support structure at 230 C and the Alloy 910 Nylon for the model at 260 C.

This actually worked quite well and I was able to separate the two parts reasonably easily.

The PVA material arrived today and that worked better giving a really good bond to the nylon and a good finish.

The dissolving in water wasn't as quick as I had hoped but after about 30 mins in fairly hot tap water it all softened enough to clean out quite well but longer soaking would probably be better.

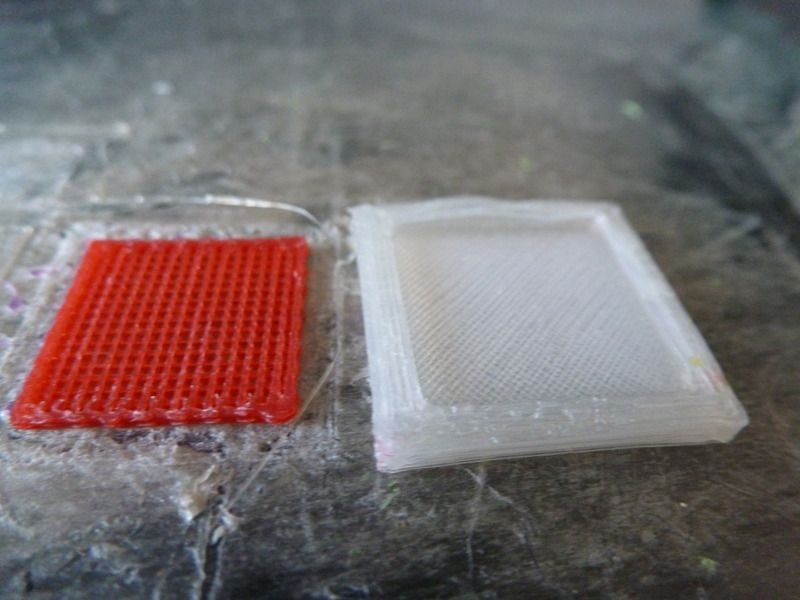

Below you can see the two parts produced the one on the left being the one using nylon and the other the PVA.

I think the PVA is the best option especially in hard to reach places but like the nylon the PVA is prone to moisture uptake and as the sample had been out of its sealed bag for some time there was a lot of moisture boiling off during the print process.

I stuck some of it in my oven for about an hour but seem to have over done it a little at it has gone a bit brittle so I I am leaving it out to see if it softens up a bit as it reabsorbs moisture.